Timeline

About me

Program/Project manager -NPI & Product Lifecycle | Ex- GE _Medical devices -Imaging Product | SIX SIGMA Green Belt| Mfg process & product Quality | QA| CAPA| LEAN|Supply chain expert

Education

University vishweshwaraya college of engineering

2007 - 2011Bachelor of engineering - be electrical and electronics engineering

Experience

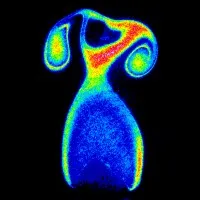

Ge healthcare

Jul 2011 - Feb 20241. Responsible for driving & owning overall QMS compliance for diagnostic imaging device business at site. 2. Development and deployment of procedures; monitoring of production & process controls for the diagnostic imaging device business at site.3. Execution of transfer programs (design, manufacturing, supplier); 4. Driving improvement opportunities via product, process and quality system Corrective And Preventive Action (CAPA) activities; 5. Driving the training metrics.6. Driving lean initiatives leveraging six sigma tools. Proponent of DMAIC methodology.7. Trained for Risk management activities recording & documentation and solely responsible for the management of Risk Management File for the products handled - Pfmea8. Preparation and conduction of Total quality and Management Reviews9.Enable sustenance & improvements of established Quality System for increased effectivenessat siteAudit:1. SPOC for MDSAP audit readiness. (Medical Device Single Audit Program for US FDA, Health Canada, and Australia, Brazil and Japan's Administration). Hands-on with 6 MDSAP audits as SME. 2. Participated in site audits as SME: IMDR by CDSCO India, UL, FDA, Intertek, ANVISA Show less Project Lead:1.Execution of MRI System product transfer to Bangalore site, ensuring all QMS and Manufacturing activities are compliant for smooth transfer2.Lead the transfer of MR Magnet by providing hands on training and technical guidance on product educated from International assignment at CHINA.3.Own & Lead the implementation of digital transformation projects at site -UDI, Tableau, electronic device history record & electronic Defect management system4.Develop, Verification & Validation of all manufacturing process for successful transfer of new products - MR Cabinet, Ultrasound probes , MR Magnet.5.Establish Manufacturing Process and BOM structure by reviewing Engineering drawings & specifications6.Responsible for ensuring design outputs release & milestone deliverables7. Create and Own Project plans & Post release Project Plans w.r.t seamless transition for production Show less Process Engineering: 1. Establish & Maintain the Process of building and testing Products. 2. Responsible for monitoring and measurement of processes - improving First Pass Yield and DPU3. Driving culture of process improvements and kaizen among production associates. Driven significant number of Kaizens and Poke-yoke. 4. Driving brilliant factory initiatives and simplification projects through lean six sigma concepts;5.Reviewal & updation of SOP’s/Procedures/DHR based on Design Changes/Process Improvements/feedback from Customers6.Develop, Verification & validation of all poka-yoke Jigs & fixtures used for manufacturingprocess.7. Ensure Preparedness for audits by FDA Audits, global Quality council (GQC) audits, GMED audits, MDSAP, Audits by Certification/Test Labs, Quarterly internal quality audits.Product Quality:1. Driving product quality for MR subsystems ( RF coils and Gradient amplifiers +power supplies)2. Root-cause analysis for manufacturing defects for products owned. 15+ product catalogues of RF coils and gradient amplifiers & power supplies part of MRI system.3. Owning materials review board and driving cost of quality culture with suppliers. 4. Working with suppliers across continents to reduce part defects and improve product quality. Audited multiple supplier and collaborated for multiple action implementations. 5.Ensure Closure of non-conformities using RCA & CAPA process.Change Management:1. Design change implementation; Initiation of design change for manufacturing related activities.2.Monitor and ensure timely Execution of Engineering Changes Order (ECO) with constant interaction with the cross functional teamsNew Product Introduction:1. Line readiness; Establishing Z-score.2. Driving process excellence. 3. Product transfers and release to productionDigital Transformation:1. Hands-on experience on MES Application like eDHR. Product route creation, to back-end testing, to validation and implementation. Show less

Quality Assurance Lead

Nov 2019 - Feb 2024Senior Manufacturing Engineer

Jan 2016 - Oct 2019Manufacturing Engineer

Jul 2011 - Dec 2015

Cisco

Aug 2022 - nowProduct lifecycle project manager

Licenses & Certifications

Iso 13485:2016 lead auditor

BsiDec 2021

Lean six sigma green belt certification

Ge healthcareAug 2015

Mini-course mdr 2017/745

Easy medical deviceDec 2021

Foundation of leadership

Ge crotonvilleMay 2016

Change acceleration program

Ge crotonvilleSept 2017

Recommendations

Bruno da ronch

Italo/Brasiliano - Senior Performance Engineer at General MotorsIndaiatuba, São Paulo, Brazil

G m sharat chandra

Chief Manager - Grid Controller of India LimitedDelhi, India

Chia-chun weng翁嘉駿

Mechanical EngineerTaipei City, Taipei City, Taiwan

Nagenderan s

QA Engineer | TOSCA Automation | IBM Sterling OMS | RetailCuddalore, Tamil Nadu, India

Junaid rathore

Senior React Developer @ SparkAi | MernStack React.js, Node.js,Lahore, Punjab, Pakistan

Aritra majumder

Project Execution | PGDM in Project Management | Project planning and Control| Oil & Gas| Modulariza...Pune, Maharashtra, India

Gustavo solari neumann

Second Year Student of B.Sc. International Management Double Degree German-Brazilian (IMX) @ESB Busi...Reutlingen, Baden-Württemberg, Germany

Mac mcelroy

Senior Global Internal Audit / Risk Assessment LeaderGreater Philadelphia

Luciano grande

Associate Commercial Director en S&P Global PlattsArgentina

Fay ivana karin

Fullstack Web & Android | ex-MSIB Batch 7 Mobile Development Dicoding Indonesia | ex-Fullstack Web &...West Java, Indonesia

Renato viana

Professor de Ciências | Ciências Ambientais, Biologia MolecularSabará, Minas Gerais, Brazil

Tomas leffler

Adjunct Lecturer at Chalmers University of Technology & Development Engineer at Vattenfall AB Heat S...Älvkarleby, Uppsala County, Sweden

Dilshan fernando

Graduated from Faculty of Engineering , University of Peradeniya Specialized in Electrical and Elect...Kalutara District, Western Province, Sri Lanka

Jiří abel

Business Unit Program Manager ve společnosti Shape Corp.Central Bohemia, Czechia

Latoya jones

Math Academic Interventionist at Memphis Virtual SchoolMemphis, Tennessee, United States

Qingqing lin

VPChaoyang District, Beijing, China

Hugo moura

Parinox Energia Manager / Pecol Automotive Technology and maintenance ManagerÁgueda, Aveiro, Portugal

Alex vuginshteyn

EXECUTIVE VICE PRESIDENT AT CICRAUN INTERNATIONALLYBrooklyn, New York, United States

Christiane tamiyang silalahi

Product AssociateJakarta, Indonesia

Chris hearn

Head of Support & Customer Relations / Hardware Manager at Sharp-aX Computer SystemsTring, England, United Kingdom

...

Deep Enrich

Deep Enrich