Timeline

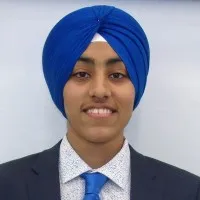

About me

GET @ Thirumalai chemical limited || MBA' 2025 (P&O) || EX. Vice President (EMC & Ananta'22) || GSFC' U' 2023 (CHED)

Education

Newer high school

-Hsse

Little flower high school

-Ssc

Amity university online

2023 - 2025Master of business administration - mba production & operation

Gsfc university

2018 - 2023Bachelor of technology - btech chemical engineering

Experience

Event management club

Nov 2020 - Apr 2022I had my role as a secretary at event management club of Gujarat state fertilizer and chemical university. Because of this post I love to interact with a new faces and I truly believe in leadership so it’s nice place where I can engaging my self with different lookout(prospective) person.

Vice President

Sept 2021 - Apr 2022Secretary

Nov 2020 - Aug 2021

Indian oil corp limited

Nov 2021 - Nov 2021Visitor

Transpek industry ltd

Dec 2021 - Jan 2022Process engineerStudied TC production with PFD, P&ID, Safetyaspects, process operation and shutdown process. Also, designeddistillation tower, pressure drop of pipe, pipeline sizing. Moreover,I have suggested one change in the pump which may reduce their operating cost.

Gujarat state fertilizers and chemicals ltd

Jun 2022 - Jul 2022Process engineerAt GSFC ltd, I had allotted OGT (off gas treatment) plant. Where I had calculated overall material balance, energy balance on catalytic converter. Moreover, I would also able to find out how much steam was required during heat transfer process and water loss in colling tower during the process. Furthermore, I had also designed pressure drop and pipe design of material line.

Takviksh engineering pvt limited

Feb 2023 - Apr 2023Project intern (process design)Studied and Designed "Air Pollution control Plant" with guidanceof highly knowledgeable team of firm. We designed equipment'slike. Heat exchanger, KOD, Venturi, Scrubber, Pump, Blower, PSVs,Tanks and Chimney, and we developed PFD and equipment list ofit.TakViksh Engineering is, FEED, Detailed Engineering, Procurement, Construction Management (EPCM) Consultant, Project Management Consultancy (PMC) and Plant Manufacturing company based at Vadodara, India.

Thirumalai chemicals ltd

Jun 2023 - nowProcess engineer (get)Exposure to the production process of Phthalic Anhydride (PA),which involves the gas-phase oxidation of ortho-xylene usingcatalysts.largest Phthalic Anhydride oxidation reactor in India withTubular Fixed bed Catalyst of 25000 tubes.Got exposure of Phthalic anhydride tubular exothermiccontinuous reactors, Thermic fluid Heaters, Boilers, Blowers, Aircompressors, Distillation columns, Ejectors, Air dryer systems,Hydrocarbon storage and handling and related steam networksystems.Assisted in the development and improvement of manufacturingprocesses under the guidance of senior engineers.Conducted analysis of production processes to identify areas foroptimization, contributing to reduced cycle times, wasteminimization, and improved yields.Learned and adhered to standard operating procedures (SOPs)for production processes, actively engaging in training sessionsto enhance understanding and proficiency.Contributed to the implementation of real-time monitoring andcontrol systems for production processes, assisting inmaintaining consistent product quality and compliance.Assisted in troubleshooting efforts to identify and resolveprocess-related issues, gaining valuable experience in crossfunctional collaboration and problem-solving.Supported quality assurance measures and audits to ensurecompliance with regulatory requirements, industry standards,and internal quality management systems.Assisted in maintaining comprehensive documentation ofproduction processes,including batch records, processparameters, and equipment logs, to support reporting and analysis.Actively engaged in continuous improvement initiatives tocontribute to operational excellence, cost reduction, andproductivity enhancement across the production facility.Maintained awareness of safety protocols and environmental considerations, adhering to regulations and best practices to ensure a safe and sustainable work environment. Show less

Licenses & Certifications

Natural gas engineering

NptelJul 2021- View certificate

Basic of disaster risk management

Interlink enterprisesSept 2020 - View certificate

Energy: the enterprise

CourseraSept 2020 - View certificate

Our energy future

CourseraNov 2020

Languages

- enEnglish

- guGujarati

- hiHindi

Recommendations

Mark laris

Chief Nuclear Engineer at Reactor Engineering Services (Retired)Denton, Texas, United States

Christina cooper young

Director at Charles SchwabPhoenix, Arizona, United States

Erik malmedal salhus

Software Engineer and Partner @ SceltoOslo, Oslo, Norway

Kate wales

Sales Consultant - Intrepid TravelCalgary, Alberta, Canada

Pavitpaul makkar

B.S. in Biomedical Engineering @ UF | Product Design Engineering Intern at ExactechHollywood, Florida, United States

Chikkanna ramanathan, pmp®

Planning Engineer | Quantity Surveyor | Estimation | Billing | Project Coordination | Project Manage...United Arab Emirates

Ebin emmanuel

Architectural 3d exterior and interior designerKerala, India

Pavan kartheek

Senior Quality Assurance Analyst at MOTOR Information systemsHyderabad, Telangana, India

Muhammad jawad khan

Assistant Vice President Creative DepartmentKarāchi, Sindh, Pakistan

Gerard tappenden

IT ProfessionalKent, England, United Kingdom

...

Deep Enrich

Deep Enrich