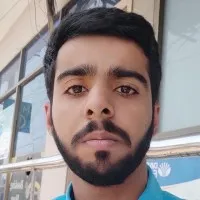

Rajiv Saxena

Asst Maintenance Engineer

Connect with Rajiv Saxena to Send Message

Connect

Connect with Rajiv Saxena to Send Message

ConnectTimeline

About me

Asst. General Manager- Plant Engineering, Greenfield Projects, Maintenance, Facility Mgmt, Safety & Utility

Education

Bhilai Institute of Technology, Bhilai

1986 - 1990Bachelor of Engineering - BE Electrical Engineering 1st Class/ 68%

Experience

Gajara Gears Limited

Jun 1991 - Mar 1993Asst Maintenance Engineer• Gained exposure to power circuit & control circuit diagrams of various Gear Making machines

Bharat Zinc Limited

Jun 1993 - Jun 1994Maintenance Engineer• Worked on 33KV sub station yard, HT panels, DG sets, compressor, rectifier transformer & over head cranes.

.webp)

Jaya Hind Industries Limited (Firodia Group)

Jul 1994 - Feb 1995Maintenance Engineer• Handled the maintenance operations for sub station, compressors & di casting machines.• Actively involved in the erection & commissioning of pressure di casting machine.

.webp)

Finolex Cables Ltd (JFTC Division)

Mar 1995 - Feb 1997Production EngineerHandled the production operations involving stock & raw material handling.• Involved in the erection & commissioning of Drum Twister machine of Seeco Make, Canada.• Brought down the machine down time by 50% through effective coordination with the maintenance department

Kromberg & Schubert Motherson Sumi Systems Ltd.

Feb 1997 - May 2000Team Manager- Maintenance Joined as Maintenance Engineer Rose to Team Manager (Maintenance, Cockpit Production & Quality) in Jan’99: Led the maintenance (preventive & predictive) functions, production & quality in the unit; for cockpit assembly of Mercedes Benz cars.Assignments & Accomplishments;• Achieved about 25 fold savings through successfully developed Online testing facilities for wiring harness & indigenized testing board for wiring harness. • Increased productivity by implementing team targets & area ownership concept.• Brought in savings through reduction in material hold ups. Introduced FIFO & JIT.• Received appreciation letters for Design & development of testing facility for wiring harness & front foot unit for auto industries Show less

Haden International Group India Pvt. Ltd. For L&T John Deere India Pvt. Ltd

May 2000 - Jan 2004Manager- M & EManager (Mechanical & Electrical): Managing the technical services to clients namely L&T John Deere Pvt. Ltd., Foseco India Ltd. & Siemens.Key Assignments & Accomplishments;• Implemented QS 9000 procedures for plant maintenance at L&T John Deere Pvt. Ltd., Foseco India Ltd., Intel, Cipla and Siemens.• Achieved savings to tune of Rs. 40 lacs for L&T John Deere Pvt. Ltd. through optimization of energy & electricity consumption.• Recognized & highly appreciated by external auditors for preparing Best Documentation during QS 9000 audit.• Appreciated by the management for• Design & development of 12V DC electrical indication arrangement for 2 x 22KV Incoming feeders.• Foolproof modification of LPG Vaporizer circuit• Implementation of QS 9000 procedure• Fixed maximum demand controller and Modification in APFC panels & CG transformer Show less

Integrated Property Management & Services Ltd. (M&M and ILFS group)

Feb 2004 - Mar 2006Head Operations PuneManaging the operations at 15 sites and successfully implemented electro mech & other routine operations for IBM, vCustomer, Kanbay, Citibank, HDFC Chubb, Honeywell Ltd, Siemens, VSNL & RMZ Corp.

Enkei Castalloy Ltd.

Mar 2006 - May 2009Dy General Manager - Maintenance & ProjectsSuccessfully completed & started three production plants for Alloy Wheels, Die-casting & Paint Shop. Also involved in achieving additional power sanction, MPCB consent & ETP/STP plants, LPG Bullet, Water Softener Plant installation, commissioning & operation. 6x750 KVA DG Set Synchronization at 2 locations, Horizontal and Vertical Machining Centers, Co2 Flooding systems at Paint Shop, Factory Inspector approval and liaison with Town Planning Department. Visited to Enkei, Thailand for Energy Savings Project. Successfully implemented many Savings Projects in Enkei India, 3 Plants Show less

Innoventive Industries Limited

Oct 2009 - Jan 2011Sr. Manager- Maintenance & ProjectsMaintenance of Tube Mills for Manufacturing of ERW and CEW Tubes from 9mm to 114mm in diameter. Maintenance of Solid State Welders up to 350Kw, Induction Furnace up to 500Kw, Tube Drawing on Draw Benches, Tube Straightening Machines, NDT for finding open and weak weld tubes, Surface Treatment Plant and Utilities like Boilers up to 5Lack K Cal, 2000KVA+ 2x900 KVA Transformer, 2x1250KVA Synchronized DG Sets. Water Softener Plant , DM Plant for Process Water and 22KV HT yard

Endurance Technologies Private Limited,Midc-Chakan,Pune

Jan 2011 - Apr 2013Sr. Manager- Maintenance & ProjectsMelting Furnaces, Gravity Die-casting machines, Heat Treatment Furnaces, CNC Turning, VTL and HTL machines. VMC and Valve Hole Drilling Machines. 2.5MVA Transformer, 750kvax2 Synchronised DG Power, 350cfmx5 Kaeser Compressors, Fire Engine, PNG project completed successfully, Paint Shop, RO Plant and 22KV HT Sub Station

Alicon Castalloy Limited

Apr 2013 - Nov 2019GM- Plant Engineering, Projects, Maintenance & SafetyGreenfield Projects, Facilities Management, Procurement of Equipment, Participation in Civil, Electrical and Mechanical related activities for erection of production shed, Erection & Commissioning of Manufacturing, Machining & Utility Equipment / Handing over the project to Production, Maintenance of Machinery & Utility equipment, Implementation of various systems and training to various level of employees for smooth operations. Statutory Compliance, Safety, Liasoning with Govt officials-MPCB, MSEDCL, Factory and Electrical Inspector, 5S and TPM activities Show less

Consultant for Foundries & Workshops

Nov 2019 - Jul 2023General Manager/ Advisor- Projects/Maintenance/Facility Manager/ Safety/ Utility/ Greenfield ProjectGeneral Manager, Electrical Engineer, 29 yrs Experience in Plant Engineering, Production, Projects, Utility, Greenfield Projects, Facility Management, Foundry Machinery & Equipment, Preventive & Predictive Maintenance, Analysis of Breakdown, Action Plan to Reduce breakdown. Energy Saving Projects, Kaizen and 5S & TPM implementation, Liasoning with MSEDCL, MPCB, Factory & Electrical Inspector, Toyota Safety System 'Stop 6+2', Safety Committee Head, Safety Audits, Internal Auditor, Handling Client Audits, Making Layouts for Single Piece Flow, Preparing SOP for various process and Safety, Legal Compliance related to Plant Engineering, Safety & Maintenance, Training to Employees for various process, Safety and Cultural Pillars, Inhouse Tool Room for making Spare Parts of various Machines, Startup of Corporate or Industry for Technical and Soft Activities, Having Electrical Supervisor Licence of Maharashtra which is mandatory for handling High Tension Line and Switchgear, Team player, Team Building, Training to employees on Multitasking Show less

Aurangabad Electricals Ltd

Dec 2020 - nowAGM - Maintenance & Utility

Licenses & Certifications

Industry 4.0

Tata Steel (Online Course during Lockdown)Jun 2020

Internal Auditor Certificate for ISO 14001 & OHSAS 18001

Indian Management ConsultantMay 2012

Electrical Supervisor Licence, Maharashtra

Govt of MaharashtraMar 2003

Internal Auditor Certificate for QS 9000 Audits

Nathan & Nathan Consultants Pvt LtdJan 1998

CII Certified Expert in Climate Change & Environmental Sustainability

Confederation of Indian IndustryJul 2020

Recommendations

Mark villiott

Software EngineerSeattle, Washington, United States

Stella marques

Social Media | Autista Suporte Nível 1 | PCD | Gerenciamento de Mídias | Criação de ConteúdoBelo Horizonte, Minas Gerais, Brazil

Amisha agarwal

UI/UX/Graphic Designer | Creating Engaging Digital Experiences | Human- Centered Design AdvocateGurugram, Haryana, India

Seyed ali emami

D.V.M. , D.V.Sc. ,Board Certified Veterinary SurgeonIran

Alessandro matalone

Digital Marketing Consultant | Advertising ManagerMilan, Lombardy, Italy

Stepаn rogonov

Unity Developer at ANappMinsk, Belarus

André luiz tedesco

Especialista de Tecnologia e Operações | Banco SantanderSão Paulo, São Paulo, Brazil

Sergio dubón

Premier Customer Service Supervisor | Customer Care Coach | Customer Care Representative | Healthcar...Guatemala, Guatemala, Guatemala

Ghinea dragos

Planning & Acquisitions Coordinator at SC Haulotte SRLPiteşti, Argeş, Romania

Teuku muhammad alghifari

Fresh Graduate, Bachelor of ArchitectureNorth Sumatra, Indonesia

Sabine cabanes

Conseillère Technique Territoriale Insertion PJJTours, Centre-Val de Loire, France

Louise kroon

Project Manager | Netherlands Foreign Investment Agency | LondonRotterdam and The Hague

Jose paniagua

VP, Treasurer at Inspire BrandsAtlanta, Georgia, United States

Paul sabu

Engineer @ IgnitariumKerala, India

Ross bartlett

Director - Transaction Advisory Services at Moore Johannesburg | CA(SA)City of Johannesburg, Gauteng, South Africa

Shaleena baghani

"""Workday Certified Graduate | Passionate about HR Technology and Process Optimization | Empowering ..."Hyderabad, Telangana, India

Magdalena barczyk-trzeciak

Application Development Manager at AccentureZurich, Switzerland

Ntobeko nkosi

Senior Technical Support IECCity of Johannesburg, Gauteng, South Africa

Ayushi p.

Psychologist | Higher Education | ResearchIndia

Moazam ali

Software Engineer HU 24'| Cyber Security| Python | AWS | AzureLahore, Punjab, Pakistan

...

Deep Enrich

Deep Enrich