Timeline

About me

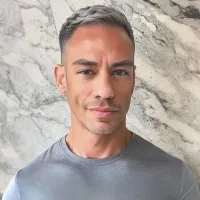

Experienced Senior Mechanical Engineer

Education

Oregon institute of technology

1992 - 1996Bachelor’s degree mechanical engineeringActivities and Societies: ASME Member since 1995

Experience

Climax portable machining & welding systems

Oct 1997 - Jan 2016Senior design engineerDevelop creative solutions to continuously improve the quality, value, and performance of the standard product line while looking for ways to reduce cost, warranty, lead-time, assembly time and manufacturing complexity.Train, mentor and guide Junior Engineers and Machine Designers in all areas of engineering process, problem solving, root cause analysis, and company procedures.Support Manufacturing, Manufacturing Engineering, and Assembly by providing problem solving, root cause analysis, and warranty investigations for 26 complex standard products.Research and resolve customer issues and support cross-functional questions/projects related to standard products from Sales, Marketing, Accounting, Applications Engineering, and Purchasing.Support, maintain and improve interdepartmental processes such as the RFEC/ECR/ECN system and lead the PLM Team. Show less

Dwfritz automation

Aug 2016 - Feb 2024Senior mechanical engineerSenior Mechanical Engineer - Metrology Systems Lead Mechanical Engineer in a multidisciplinary team that developed a precision multi-sensor non-contact metrology platform as a new product to market yielding two patents. • Productized a novel metrology machine platform that included a granite mounted 6-axis stage with a gantry loaded with laser, confocal, and interferometer sensors and micron repeatability.• Designed, developed, and tested 4 different versions of a confocal sensor extension assembly which extended two confocal probes independently 126mm using pneumatics and then released them into a kinematic mount that provided sub-micron repeatability all in a 50mm x 50mm space.• Led the team to develop a new double gimbaled stage that was repeatable to 3 microns and gimbaled to prevent bending or twisting of the gantry bridge allowing repeatable motion.• Automated the tool change process by designing a rotating swapable probe and optical alignment stage for an interferometer that allowed the machine to automatically change probe sizes and styles with sub-micron repeatability. It resulted in a pending patent.• Trained, mentored and guided other Engineers in all areas of engineering process, problem solving, root cause analysis, design for manufacturing, and design for assembly.• Designed precision assembly and calibration tools for optical alignment and concentricity. Designed thermally controlled options for the product, calibration artifacts, and testing apparatus for ISO10360 requirements. • Led the design team that leveraged the technology of the above machine to create custom calibration benches to test and validate metrology sensors to improve their accuracy.• Created novel solutions for holding nests and handling systems for automated loading and unloading of unique customer parts into metrology machines using robots of various types for 100% production level inspection. Show less

Licenses & Certifications

- View certificate

Garrett headrick

Oregon state board of examiners for engineering & land surveyingDec 2014

Volunteer Experience

Served as a Den Leader, Committee member, and Treasurer for the Boy Scouts of America

Issued by Boy Scouts of America, Cascade Pacific Council on Mar 2008 Associated with Garrett Headrick P.E.

Associated with Garrett Headrick P.E.

Languages

- enEnglish

Recommendations

Diana pinheiro machado

Formada em economia pela UnicampFortaleza, Ceará, Brazil

Natália veiga

Product & project managerSão Paulo, São Paulo, Brazil

Chukwuebuka igbo

--Product (UI/UX) designer || AI Engineer || Flight Dispatcher || Electrical/Electronics Engineer (i...Lagos, Lagos State, Nigeria

Mariana louise

Senior Product Designer | Design SystemPorto Alegre, Rio Grande do Sul, Brazil

Santhoshkumar b

Software TesterVirudhunagar, Tamil Nadu, India

Mislina elif açıkgöz gedik

IT & Process Assurance Manager at PwC TurkeyIstanbul, Türkiye

Gábor szádovszky

Software Engineer at DremioDeutschland

Gustavo morales v.

Responsable departamento de tráfico nacional e internacional/ National and international freight man...Ourense, Galicia, Spain

Divyanshi mishra

Product Manager at Inventis Technosys Pvt. Ltd.Solan, Himachal Pradesh, India

Eric smethurst

Project Leader at Department of National DefenceNorth Saanich, British Columbia, Canada

Tom matherne

Chief steward at Hornbeck OffshoreHouma-Thibodaux Area

Omar moharram

Digital MarketerAlexandria, Egypt

Greg rast

CTS, A/V System Design Engineer, Automation Programmer, DSP ProgrammerOkemos, Michigan, United States

Carmel laurentia

Computer Science Student @ Seattle University | Software Engineer @ Amazon via Seattle University Se...Seattle, Washington, United States

Douglas oliveira

AVP; Operations Manager at Bank of AmericaSão Paulo, Brazil

Jl ryncy reyes

Underwriting Manager | Canadian Business Development and Research Associate | Mortgage Loan Officer ...Batangas, Calabarzon, Philippines

Marcus g.

Graduate Student @ Georgia Tech for AnalyticsNew York, New York, United States

Jonathan fernandini

Senior Product DesignerPompano Beach, Florida, United States

Michał szyluk

Automatisation Adisor for windows IndustryWrocław, Dolnośląskie, Poland

James goldschmidt

Junior Project Manager @ The City of Cape Town | Industrial Engineering Honours GraduateStellenbosch, Western Cape, South Africa

...

Deep Enrich

Deep Enrich