Timeline

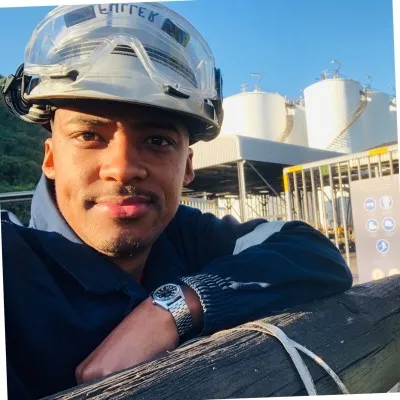

About me

IRATA Level 1 Certified Rope Access Technician | QCTO Trade Tested Welder with 7 Years Experience in TIG, ARC, MIG, and Flux Core

Education

Multi skill training centre

2022 - 2022Welding welding trade testPassed Welding Trade Test

Independent minds

2022 - 2023Asme ix welding technology/welder

Cebc training academy

2017 - 2018Welding construction engineeringActivities and Societies: Duties - Assistant-skilled welder •Shielded metal arc welding pipe (all positions) •Gas metal arc welding-carbon/stainless steel pipe (all positions •Gas tungsten arc welding-carbon/stainless steel pipe (all positions) •Combination welding-gas tungsten arc welding & gas metal arc welding pipe (all positions) •Flux-core welding pipe (all positions) •Interpretation of drawings/WPS •Use of jigs and manipulators COMPLETED – WELDING APPLICATIONS AND PRACTICES NQF LEVEL 4

Rodcon training academy

2014 - 2017Welding construction engineeringActivities and Societies: Duties - Trainee •Oxy-fuel gas brazing •Oxy-fuel gas cutting •Oxy-fuel gas welding plate (all positions) •Shielded metal arc welding plate (all positions) •Gas metal arc welding-carbon/stainless steel plates •Gas tungsten arc welding-carbon/stainless steel plates/aluminum (all positions) •Combination welding-gas tungsten arc welding & gas metal arc welding plate (all positions) •Flux-core plate welding (all positions) •Gouging •Interpretation of drawings/WPS •Use of jigs and manipulator COMPLETED – WELDING APPLICATIONS AND PRACTICES NQF LEVEL 1, 2 AND 3

Fairvale secondary school

2010 - 201412

Experience

Sfundile engineering

Apr 2017 - Nov 2017Tig & mig welderOn-site location: Bidvest tanks Richards BayMy responsibilities included: - Welding pipes (1 inch to 10 inch) using TIG/SMAW procedures;- Fabricating and welding structural supports using co2 welding procedures;- Production welding for x-ray pipelines;- Welding steel trailers in various positions;- Lifting, moving, and holding or clamping work pieces to table, into jigs, or into position as directed manually or by using pry bar;- Utilize Arc Welding Process that uses a non-consumable tungsten electrode;-Moving work pieces, tools, and supplies, manually or by hand truck;- Examine pieces for defects and measure for accuracy and fit;- Utilize Stringer Technique with Single Passes on Carbon Steel;- Meeting daily production goals. Show less

Innovative industries inc

Feb 2018 - Apr 2018Double coded welderOn-sit location: Responsibilities: - Welding Carbon Steel pipe (1 inch to 24 inch) using TIG procedures;- Welding structural supports using SMAW and TIG;- Production welding for x-ray pipelines;- Welded coils in tanks;- Tank repairs;- Perform successfully all responsibilities of the Code Welder position, maintaining a minimum of 3 weld certifications;- Read and interpret blueprints with detailed drawings and dimension styles;- Prepare weld surfaces as required;- Set-up, positions and operates hand and power tools such as shielded metal arc and gas metal arc welding equipment;- Determine welder settings required on project;- Verify final weld penetration and aesthetics;- Welding prep and fit-up of steel parts;- Weld according to all appropriate codes and procedures;- Use basic measuring skills to convert English and Metric systems;- Use basic math skills to calculate and convert decimals and fractions as needed;- Monitor quality of weld using appropriate tools and measuring devices;- Check welding process to avoid overheating of parts or warping, shrinking, distortion or expansion of material;- Perform grinding, gouging, chipping operating a grinder, cutting torch, etc.- Operate forklift, as needed, according to safe operating procedures;- Performs all functions safely and follows all safety standards and procedures; Show less

Wescol engineering services

May 2018 - Dec 2018Double coded tig welderMy responsibilities included:- Managing and running production parts through the brake;- Welding 7ga-22ga together through GMAW (TIG) and (MIG) process;- Assisting with minor repairs on steel and carbon steel with proper tig and flux core operations;- Working as TIG and MIG welder on carbon/stainless steel, arc-welder for product repair, and plasma cutter;- Weld items using TIG and MIG equipment and tools, bend cut and hammer pieces to fit the correct production piece;- Fit and make xray welds on sch;- See, plasma, torch cutting and coping, lay-out, tack & fit;- Debur and separate parts manufacture from CNC laser;- Maintaining and providing upgrade on a large transfer line utilizing CNC controls;- Train to test weld parts for leaks, MIG weld, fabrication dept;- Use GTAW weld to root pass-after that weld by SMAW to filling and cupping;- Perform all kinds of welding, brazing, and cutting using gas and electric welding equipment;- Train in using various hand and electric tools such as arch welder, grinders, buffing machines;- Pass OIMO WPS performance testing for GTAW and SMAW weld test procedures on carbon and stainless steel piping materials;- Aid in positioning parts in jigs and fixtures on bench and floor, and clamping parts together along layout marks. Show less

Dk engineering services limited

Jan 2019 - Jun 2019Tig welderResponsibilities includes: - Welding instruments for boilers- Welding water lines - Welding and fabricating pipes from (1 inch /8inch) carbon and stainless steel- Inserts on tanks & welded tanks using TIG and SMAW- Welded tank floors

Goss & balfe pty ltd

Oct 2019 - nowDouble coded welderResponsibilities: - Welding of Double TIG and SMAW for 1000 m3 Tank;- Machining fabrication materials and components;- Fitting, setting, and installing fabricated structures;- Cutting and welding with a variety of processes;- Metal forming, bending, and finishing;- Repair, design, layout, and estimation;- Overseeing shop hands or helpers;- Many other industry/trade specific responsibilities

Independant minds 107

Jan 2023 - Nov 2023Trade tested welderEngaged 900m project for Sasol Wax ( 2" carbon steel MRG gas line)

Sfundile engineering cc

Jun 2023 - nowDouble coded welder

Licenses & Certifications

Safety induction

Exxaro resources- View certificate

Irata level 1

Irata internationalMay 2024

Hydrogen sulphide awareness training (h2s)

Safety unlimited, inc.Jun 2024

Working at heights training

Ezokuphepha health and safetyJan 2023

Working at heights training

Stockdale consulting

Recommendations

Chanika kariyawasam

CPA/MBA/Commercial Manager/Senior Finance Business PartnerGreater Melbourne Area

Dhivakar m

Assistant System Engineer - Desktop SupportChennai, Tamil Nadu, India

Mary pope

Practice Manager, Department of Primary Care, Martin Army Community HospitalPhenix City, Alabama, United States

Gabriel nogueira

Engenheiro Civil | Civil EngineerSão Paulo, São Paulo, Brazil

Mohamad helmi hassan

Customer Enquiry Executive at Employees Provident Fund of MalaysiaButterworth, Penang, Malaysia

Tan when young

Singapore, Singapore

Anna wilson

Trainee Health Psychologist, MBPsSUnited Kingdom

Deepinder singh

Team Lead at Watermark || Java 17 || Spring Boot || Microservices || AWS EKS || AWS Lambda || Docker...Chandigarh, Chandigarh, India

Victor de leon

Company Officer at US Navy, Naval Mobile Construction Battalion FIVEWilliamsburg, Virginia, United States

Chandrashekar rajagopal

Assistant Manager at Robert Bosch Automotive electronics India pvt LtdBengaluru, Karnataka, India

...

Deep Enrich

Deep Enrich