Timeline

About me

Packaging Professional/Innovation and Development/Chemical Engineer/Technical Customer Representative

Education

Institute of packaging sa

2018 - 2018Diploma: packaging technology packaging technology (cum laude)

University of south africa/universiteit van suid-afrika

2020 - 2023National diploma chemical technology/technician

University of the free state

2009 - 2012Bsc(agric) agricultural economics/food science bachelors degreeActivities and Societies: Peer Educator Primarian committee member (House Akasia) Mentored first year students.Served in the House committee

Experience

.webp)

South african department of agriculture, forestry and fisheries (daff)

Feb 2014 - Jan 2015Production management intern• Determined the failure rate in vacuum packed beef primal in terms of pack integrity using the Ishikawa and Pareto models and ascertained the cost implications thereof.• Determined the metal threshold for beef.• Formulated a low budget beef patty from brief to a market sample and conducted sensory evaluations for this product.• Conducted an experiment on tallow on behalf of a farm.• Planned dispatch activity based on customer orders and truck availability, arranged for all logistics based on veterinary and quality regulations and standards, and ensured that controls were in place to minimize pilferage, enabled stock control and satisfied logistics requirements and regulations.• Identified a department which was losing productivity and aided it into increased productivity using 6 Sigma, Lean Manufacturing, Kaizen and Kanban principles.• Drew a blueprint of a department to determine manning levels and task adequacy.• Worked on the dynamics of stock control and stock movements and production reporting and accountability.• Kept a register for all the staff in a department in order to observe the trend in absenteeism and to help the supervisors to efficiently monitor staff attendance.• Investigated time wasted during break times, communicated with the relevant parties involved and devised a solution to reduce time wastage and thus increasing productivity. Show less

Karan beef

Feb 2015 - Jul 2022•Managing packaging department. • Participating in the audit program. • Maintenance of QMS based on ISO 9001:2015. • Implementation of and control over the Food Safety Systems requirements based on ISO 22000:2005. • Food Safety Team member. • Maintaining safe work environment by enforcing standards and procedures as well as compliance with legal regulations as per industry spec. • Responsible for the implementation of HACCP programmes and ensuring adherence in the factory.• Conducting validation studies.• Ensuring documentation relating to Food Safety programmes are properly kept and well maintained. • Developing SOPs.• QC of final product and verifying the authenticity of label information against packed content. • Customer relationship including improving productivity and ensuring high return, ensuring minimum wastage and maintaining relationship between the organisation and customers. •Drafting product specs.•Setting up packaging dept goals and KPI’s to align with the company's goals and targets• Central liaison between the organisation and packaging material suppliers with a key focus on the improvement of packaging materials ensuring compliance in regards to product specification. Responsibilities include problem-solving, introduction of new as well as re-engineering of existing packaging materials. • Leading the end to end process of packaging materials for the entire organisation. This entails: on-line process, quality control, testing new packaging on the production line, from delivery through to dispatch until it reaches the customer• Leading the process of Non-Conformance through compiling, reporting and distribution of Non-Conformance Reports•Leading and facilitating presentation regarding packaging materials and packaging material suppliers to contribute to effective decision making with Management• Providing technical training to employees with regards to operational aspects of new and existing packaging equipment and programme Show less Determined a work flow rate of the entire de-boning department from input to output to help the department’s management set the line speed at a rate which will maximize productivity. Determined the distribution of beef packages from the cutting tables to the vacuuming machines, the spread at which they are distributed to the vacuuming machines and the efficiency of the vacuuming machines, this helped significantly reduce pile-ups on the cutting tables and the packing hall. Determined the average performance of output terminals in the De-boning department, this helped determine the efficiency of each output terminal operator and helped the department’s management to optimize the productivity of each output terminal operator Show less

Food Scientist/Packaging Technologist

Mar 2015 - Jul 2022Volunteer (Production Management)

Feb 2015 - Mar 2015

Mpact limited

Jul 2022 - now• Managing the Customer Complaint Handling (NCR) system – including registering, issuing, investigation, visits, corrective / preventative actions, reports and feedback to customers, daily and weekly reporting. • Customer Technical Support, including Technical visits, Customer production line liaison, Technical Market Watch (product value chain) and Product optimisation • Customer Trials – Managing trials on-site, consolidating information between sales and production, ensuring that trial runs as efficiently and effectively, liaising with customers and signing-off new jobs. • Benchmarking• Product optimisation and development. • Paper optimisation – assisting with projects to rationalise, optimise and improve paper costs Show less

Innovation and Technical Representative

Jul 2024 - nowCustomer Technical Support

Jul 2022 - now

Licenses & Certifications

Iso 9001:2017 quality management system implementation

Sgs s.aJun 2017

Food safety team workshop based on iso 22000:2005

Progress excellenceSept 2015

Fssc 22000

Entecom food safetyFeb 2023

Languages

- enEnglish

- tsTshivenda

- seSesotho

- xiXitsonga

Recommendations

Mohamed kamal

Software Engineerالشرقية مصر

Jennifer walker

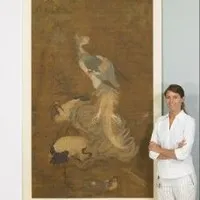

Conservator of East Asian Paintings and Artworks on PaperAlameda, California, United States

Rachel lynch

Junior Research Analyst at Abbey Capital LimitedCounty Dublin, Ireland

Thanh tam nguyen

Medical Student | Doctor of Medicine - MDFerrara, Emilia-Romagna, Italy

Sirirat rattanapituk

Marketing Lecturer at University of the Thai Chamber of CommerceBangkok, Bangkok City, Thailand

Imran basit

Tendering Manager at AMCOالسعودية

Vipul chadha

Associate Director - Data & Technology at Optum Global Solutions, UHG | Business Solution Analyst | ...Delhi, India

Gord glinka

Lead Commercial Security Systems TechnicianEdmonton, Alberta, Canada

Rutkai krisztina

Assistant ManagerGöd, Pest, Hungary

Murad zelin

Technical support engineerMoscow, Russia

Mais abu yasen

Exquisite Relationship Manager at Bank Al-EtihadAmman, Jordan

Andriele santos

Project Manager | Technology Manager | Product Manager | Martech ManagerCuritiba, Paraná, Brazil

Raymond balmès

Chief Product & Technology Officer @Septeo HospitalityBesançon, Bourgogne-Franche-Comté, France

Luuk visser

Business Development | Ceating a better labour market by Technology | +31 6 59 20 01 29The Randstad, Netherlands

Ibrahim khalid

Senior System Engineer at Corporate Projukti LimitedBangladesh

Anderson lopes dos santos mba , sfpc

PMO Professional | Project Manager | Scrum Master | Product Owner.| Governança em TI | Gestão de Con...Salvador, Bahia, Brazil

Ishan sharma

Cloudera Certified Spark Developer . Software Developer at Amdocs.Panchkula, India

Jennifer wanjiru

Credit Risk Management | Strategic Credit Management | Debt Collection | Financial Accounting | Fina...Nairobi County, Kenya

Angelique bonnardot

Marketing Manager chez Norsk HydroFréjus, Provence-Alpes-Côte d'Azur, France

Harisha krishnamurthy

Support Team Manager - C4C & CRM, Customer Experience at SAP Labs India.Karnataka, India

...

Deep Enrich

Deep Enrich