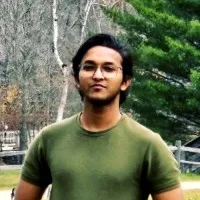

Sumudu A Weerasinghe

Computer Hardware Technician

Connect with Sumudu A Weerasinghe to Send Message

Connect

Connect with Sumudu A Weerasinghe to Send Message

ConnectTimeline

About me

Maintenance Manager at Mirage Recreational Services LLC, Dubai

Education

G / Karandeniya Central Collage

-

Open University of Sri Lanka

2010 - 2013Diploma in Technology - D.Tech Mechatronics

Open University of Sri Lanka

2013 - 2017Bachelor of Technology Honours in Engineering - B.Tech (Hons) (Eng) Mechatronics

Experience

Softland PC (Pvt) Ltd

Jan 2008 - Jan 2009Computer Hardware TechnicianResponsible for, • Sales of Computers and accessories.• OS Installation.• Computer Assembling • Computer Troubleshooting • Software Installation• Visit Customer Sites.• Networking and Network Troubleshooting• Accounting

The PC Centre (Pvt) Ltd

Jan 2009 - Jan 2010Computer Hardware TechnicianResponsible for, • Sales of Computers and accessories.• OS Installation.• Computer Assembling • Computer Troubleshooting • Software Installation• Visit Customer Sites.• Networking and Network Troubleshooting• Accounting

Brandix

Aug 2010 - Jul 2011Engineering TraneeAs an Engineering Trainee, I have gained practical experiences about,• Industrial electrical drawing, wiring, and troubleshooting.• Electronic diagrams, electronic circuit design, and troubleshooting.• Different kinds of sensors and actuators used in industries.• About controllers, such as PLC, PLR, HMI, PIC, and electrical controllers. • Automated sewing machines. • How to write technical reports and instruction manuals.• Preventive, Predictive and corrective maintenance. • Engineering CAD/CAM software such as Solid Work, AutoCAD.• Engineering simulation software such as FluidSIM, Proteus, electronic workbench, SolidWorks Electrical.• Pneumatic and hydraulic operations.• How to separate operations according to garment style.• Workshop technology.• Lathe, Milling, Welding, and other tools in the workshop.• Sewing machines maintenance. Show less

Cleanco Lanka Ltd

Feb 2011 - Nov 2012Station ManagerCleanco Lanka (Drivegreen) is a leading environmental services company in Sri Lanka. It is providing a vehicle emission test report for vehicle registration purposes. Duties and responsibilities are,- Prepared all administrative, HR, and finance documentation every month.- Well-managed customer complaints & inquiries, and provide guidelines on how to maintain properly their vehicles and the importance of emission tests.- Well-organized the customer awareness programs and improved the sales in the early stage of the company.- Successfully led the staff to achieve the given monthly sales target.- Provided the training to staff on how to doing petrol and diesel emission testing according to government rules and regulations and keeping customer safety.- Maintained the machines and work premises, and implemented the 5S. Show less

Brandix

Nov 2012 - Nov 2014Automation TechnicianBrandix is a leading apparel manufacturing company in Sri Lanka. It is providing Inspired Solutions to world-renowned brands for five-decade ego. Brandix casual wear in Sri Lanka used different kinds of sewing machines and special MIMO machines to provide a better service to customers. In addition to producing innovative machines inside the factory workshop to improve the product quality and reduce lead time. Responsible for all Understanding Sewing Operations | Gain Practical Experience All Type of Sewing Machines | Electronic and Electrical Wiring | 5000 SMV Saving per Month | Sewing Machine Repair and Maintenance| Innovation Machine Repair and Maintenance | Help to Factory Maintenance | Ensure machine Safety | Visit Production Line and Find Innovative Ideas | SMV Saving | 5S Implementation | follow LEAN Six Sigma | follow the Industrial Safety.Involved Projects are,• Designed and fabricates clean finish loop machines.• Automated conveyor type loop cutter machine.• Automated mini loop cutter machine.• Semi-automated loop cutter machine.• Semi-automated pocket hem machine.• Automatic Waistband marking machine.• Automatic elastic waistband cut and marking machine.• Fabric inspection machine.• Automated Label pick-up machine.• Label Press machine (heat seal).• Portable dust cleaning machine.• Fabric winding machine.• MIMO machines modification and repair. Show less

Creations Sewing Technology (Pvt) Ltd

Nov 2014 - Nov 2017Automation EngineerDesigned and implemented automation systems to improve manufacturing efficiency and reliability.Programmed PLC, PIC microcontrollers, Arduino boards, and other hardware/software to control processes.Developed fully automated and semi-automated machines for the garment industry, optimizing production lines.Used SolidWorks and AutoCAD for designing automation systems and components.Troubleshot and analyzed system issues to minimize downtime.Collaborated with teams to integrate automation with existing processes.Developed HMI screens and control panels for system operation.Tested and validated automation solutions for project specifications and safety.Implemented robotic automation to increase productivity and reduce errors.Optimized automation processes to enhance performance and efficiency.Applied Lean Six Sigma to drive continuous improvement in systems.Maintained documentation for automation systems, including code and schematics.Ensured compliance with safety standards and conducted risk assessments.Trained and supported operations and maintenance teams on automation systems.Worked with vendors to select components for automation solutions.Stayed updated on new automation technologies and applied improvements.Collaborated with project managers to ensure timely, budget-compliant project delivery.Achievements• Designed and fabricated pieces separating and collecting unit, and It is saved one helper labor.• Designed and fabricated pieces transferring unit between operations. It is saved one helper labor and unnecessary movements.• Designed and fabricated a small dart setter machine according to an existing machine.• Designed and fabricated a label press machine, and It is saved one helper labor. Show less

Jiffy Group

Nov 2017 - Apr 2022Led the design and development of engineering systems and components, ensuring compliance with specifications and standards.Collaborated with cross-functional teams to define project requirements and deliver innovative design solutions.Conducted mechanical design reviews to ensure accuracy, functionality, and manufacturability.Utilized SolidWorks, AutoCAD, and Siemens NX to create design drawings, schematics, and models.Performed engineering calculations and simulations in CAD software to validate designs under various conditions.Generated CNC milling G-code for fabrication parts, ensuring precision and efficiency.Ensured adherence to safety standards, environmental regulations, and quality control processes.Mentored junior engineers, promoting skill development and best design practices.Reviewed and approved design documents, ensuring all criteria were met.Collaborated with manufacturing teams to ensure seamless transition from design to production.Trained the workshop team on tool usage and safe operational practices.Analyzed and troubleshot design issues, implementing solutions to overcome challenges.Coordinated with clients, vendors, and suppliers to ensure resource availability.Maintained accurate documentation of design processes, revisions, and specifications for compliance.Applied Lean Six Sigma methodologies to identify inefficiencies, reducing waste and improving project timelines.Led continuous improvement initiatives, driving innovation and excellence in design and production workflows.Contributed to the development of new inventions, enhancing product functionality and market competitiveness. Show less Responsible for all Engineering Design and Drawing | Machine Fabrication | Grow Bag, Block and Vacuum Forming Tray Mold Fabrication | Tools Fabrication | Innovation | Machine Repair and Maintenance | 5S Implementation | CI Projects | Follow the Industrial standard | Team management | Ensure Health and Safety at JSL group.Achievements• Designed and fabricated an innovative adjustable mold for grow block production, and reduced average mold changing time from 6.5 hours to 2.5 hours as well as it is user-friendly. • Successfully automated grow block production process and save three casual laborers.• Reduced machine breakdown from 8% to 3% of a grow block machine by modifications.• Designed and fabricated grow bag machine.• Automated briquette production sieving operation and save two casual laborers. Show less

Senior Design Engineer

May 2021 - Apr 2022Design Engineer

Nov 2017 - Apr 2021

ParksonGroup

Dec 2022 - Jan 2024Engineering ManagerOversaw MEP systems integration and ensured seamless coordination between all engineering disciplines on construction sites.Managed construction site maintenance activities, ensuring that all systems operated efficiently and were maintained according to project timelines and budgets.Reviewed and approved mechanical design plans, ensuring compliance with industry standards, safety regulations, and project specifications.Supervised and optimized maintenance operations for mechanical, electrical, and HVAC systems to ensure maximum uptime and operational efficiency.Led HVAC maintenance programs, including system inspections, troubleshooting, and preventive measures to enhance system performance and reliability.Provided strong team leadership, mentoring engineers, assigning tasks, and promoting collaboration to meet project and organizational goals.Implemented and managed ERP systems to streamline maintenance scheduling, resource allocation, and reporting, improving overall operational efficiency.Ensured accurate and thorough documentation of all engineering designs, maintenance records, and compliance reports to meet industry standards and regulatory requirements.Drove continuous improvement by analyzing system performance and implementing strategies to reduce downtime, optimize energy usage, and enhance reliability.Collaborated with cross-functional teams to ensure all maintenance activities were aligned with broader project objectives, timelines, and quality standards. Show less

Mirage Recreational Services LLC

Feb 2024 - nowMaintenance ManagerDevelop and implement preventive maintenance strategies to enhance equipment reliability, minimize downtime, and increase OEE.Conduct in-depth root cause analysis to address recurring mechanical issues, leading to improved operational efficiency.Apply reliability-centered maintenance principles to optimize asset performance and lifecycle management.Manage complex maintenance engineering projects, ensuring compliance with industry standards and regulations.Proficient in mechanical engineering principles, specializing in the maintenance and repair of critical systems and machinery.Diagnose and resolve equipment malfunctions through effective troubleshooting, minimizing operational disruptions.Spearhead maintenance management programs, balancing resource allocation, budgetary constraints, and operational priorities.Promote workplace health and safety by implementing rigorous safety protocols and conducting regular training sessions.Lead cross-functional teams with strong leadership skills, fostering collaboration and delivering project goals on time.Lead engineering design efforts for mechanical systems and components, ensuring compliance with industry standards and operational requirements.Conduct thorough drawing review and approval processes to ensure design accuracy, feasibility, and alignment with project specifications.Foster a culture of innovation by exploring and implementing new technologies and solutions to enhance system efficiency and performance.Collaborate with cross-functional teams to integrate innovative design solutions, improving the overall quality and functionality of engineering projects. Show less

Licenses & Certifications

- View certificate

Associate Engineer - AEng

Engineering Council Sri Lanka - ECSLJan 2021 - View certificate

Lean Six Sigma White Belt Certification

Jiffy GroupFeb 2020 - View certificate

CI Project - Reduction of Mold Changeover Time

Jiffy GroupNov 2020 - View certificate

Associate Member - AMIE

The Institution of Engineers, Sri LankaOct 2017 - View certificate

CI Project - Increase Efficiency of Grow Bag Machine

Jiffy GroupMar 2020 - View certificate

Occupational Safety & Health

National Institute of Occupational Safety & Health - Sri LankaMar 2019

Languages

- enEnglish

- siSinhalese

Recommendations

Lauren mcnamara

Legal SecretarySydney, New South Wales, Australia

Rafael brito hernández, cissp

CISSP | Cybersecurity Audit Manager at Banco BHDDominican Republic

Andy russell

Commercial Director at Origin Amenity Solutions Ltd.Eastbourne, England, United Kingdom

Spela bovha

sales and marketing manager at MA marketing d.o.o.Slovenia

Michael osumah coren, mnse, cpm, b.eng., m.eng

Contracts & Project Engineer/Project Management/Procurement Specialist/Site SupervisorWarri, Delta State, Nigeria

Mohammad adnan khan

Jr. Quality Analyst @Tangentia ISTQB Certified Tester ...Goa, India

Thushan dewasurendra

Program Management | IFS Finance ConsultantReading, England, United Kingdom

Dan johnson

BSME, MBA, PMP, Project/Systems Engineer/LSS BlackbeltMelbourne, Florida, United States

Vivek chincholi

Java FullStack Developer@MedlinePune, Maharashtra, India

Subhas nigam

Call Center Representative at CMSKolkata, West Bengal, India

Qiqi zhang

Master of EducationGold Coast, Queensland, Australia

Jina vang

Finance Undergraduate at UNC CharlotteCharlotte, North Carolina, United States

Giuliano boschetti

Product Manager - Aviation & Yacht Finance and Commercial RE at UBS | MSc. Management EngineeringZurich, Zurich, Switzerland

Rahul m

Biological Treatment Plant Field Operator | Unit Operations, Wastewater TreatmentChennai, Tamil Nadu, India

Sai kalyan maram

Tech Consultant & MSIT Candidate @UNH | Oracle Certified Associate, Java SE 8Manchester, New Hampshire, United States

Thomas simoneaux

Director of Digital Experience - The University of Arizona Global CampusAustin, Texas, United States

Ryan lopes

Desenvolvedor de softwareBrasília, Federal District, Brazil

Rafaella alcalde

Analyst at BlackRock | MBA candidateBoston, Massachusetts, United States

Muhammad hassan farid

Computer Scientist | AI Engineer | Data Scientist | Machine Learning Engineer | Computer Vision Engi...Islāmābād, Pakistan

Kartik satpute

Student at Indian Institute of Technology, KharagpurChandrapur, Maharashtra, India

...

Deep Enrich

Deep Enrich